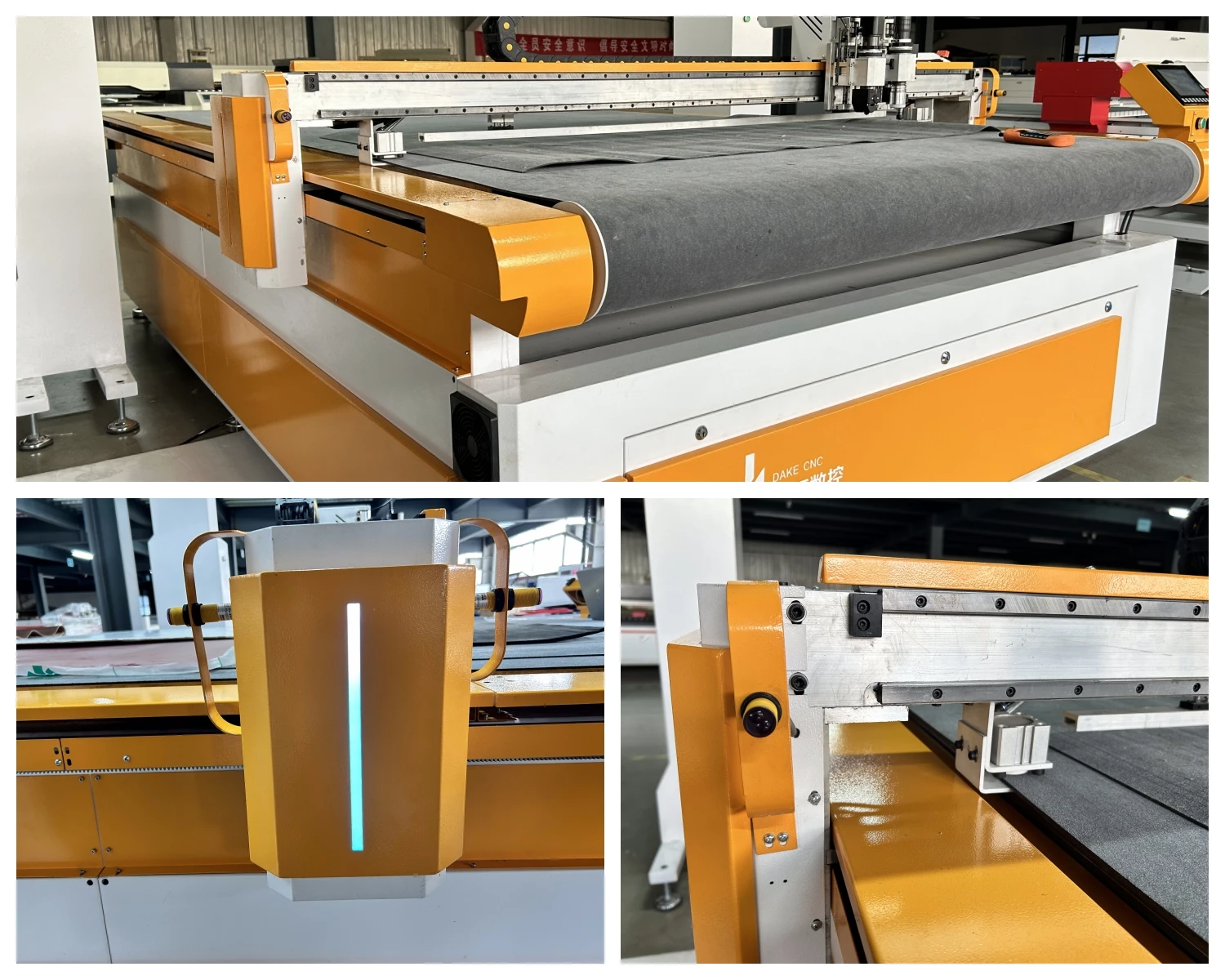

Schneiden von weichen bis mittel dichten Materialien.

* Je nach Anwendung, verfügbar mit 0.5mm oder 1.0mm Hub

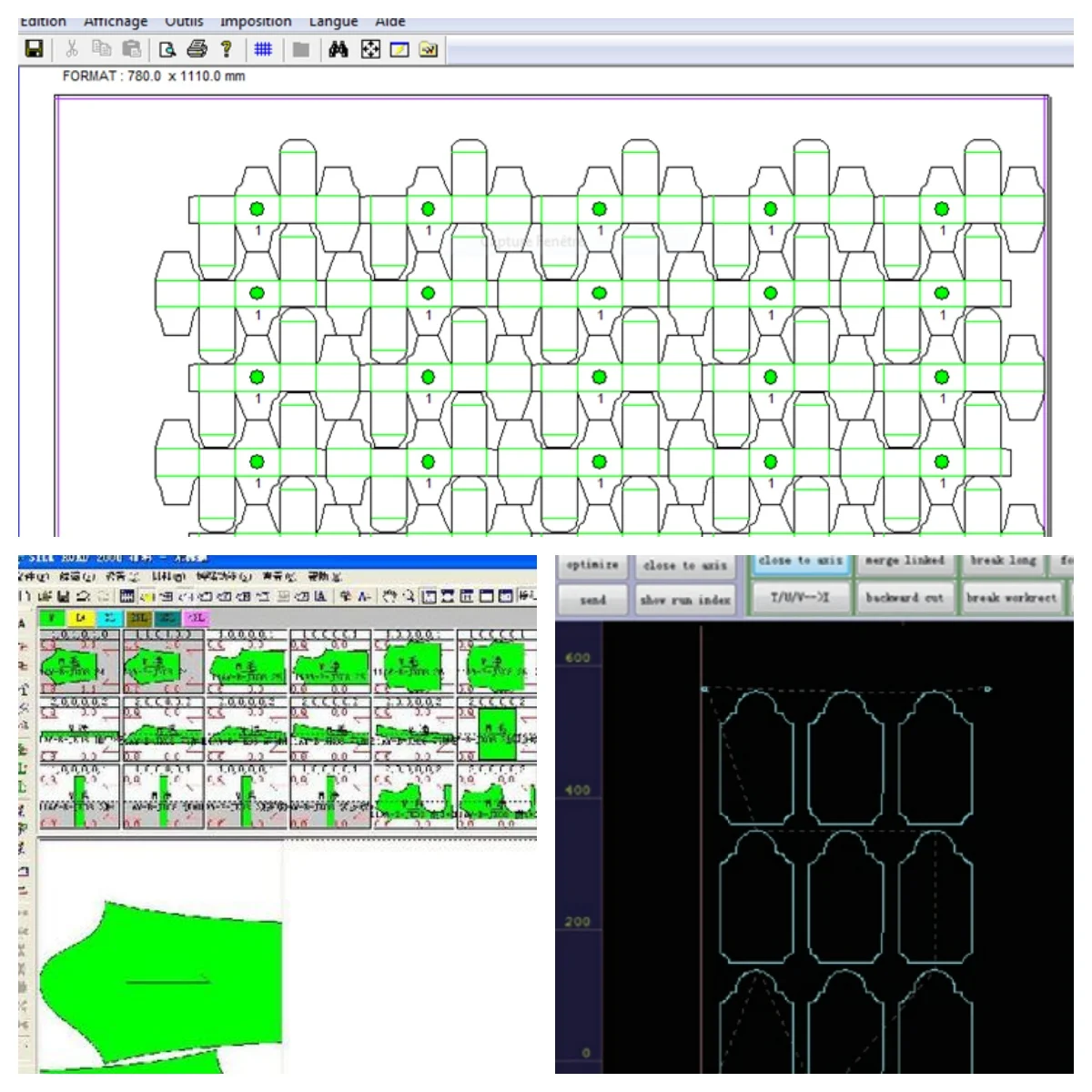

* Perfekt zum Schneiden von detaillierten Konturen

* Sehr hohe Hub frequenz

* Hohe Verarbeitung geschwindigkeiten

Material

Leder; Gummi; Doppel wand blätter; Pappe; Schaum